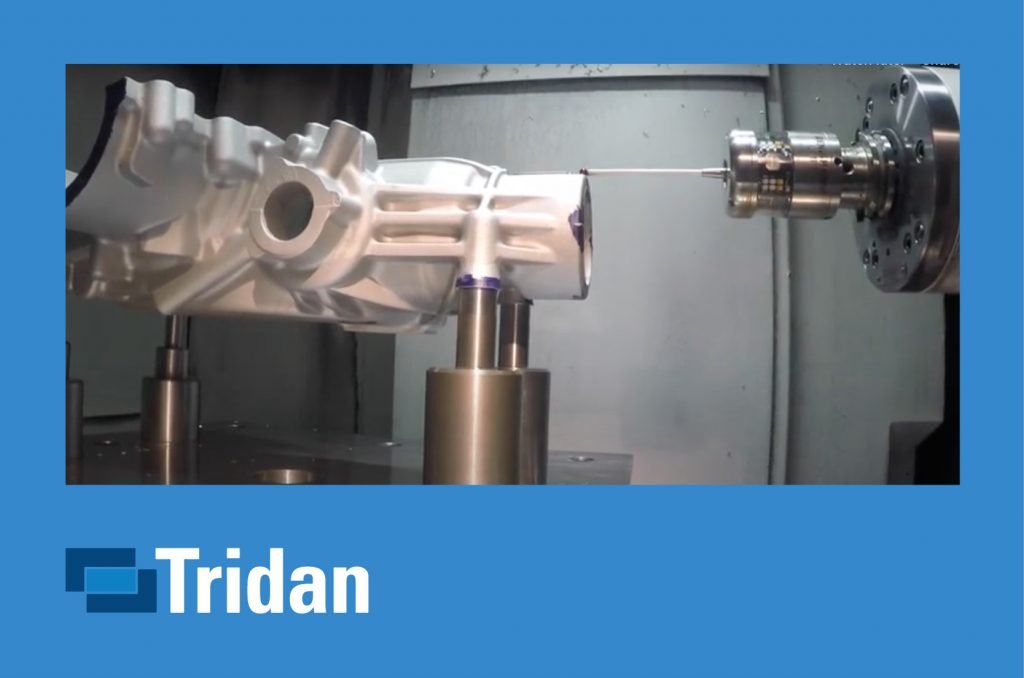

Tridan Engineering are using Renishaw machine tool probes to align complex castings as part of a motorsport machining contract for Ricardo. For the first batch of parts, a project that would normally have taken around two months, was compressed into a 17-day turnaround without any compromise in the quality standards demanded by the client.

To read more about the perfect fit for Ricardo case study