Problem

A leading European manufacturer in the food processing industry was experiencing delivery, quality and price stability with their incumbent suppliers.

Solution

After an Internet search forty-seven companies including Tridan were listed as possible suppliers. After three months of auditing Tridan were selected as a supplier of machined components.

Outcome

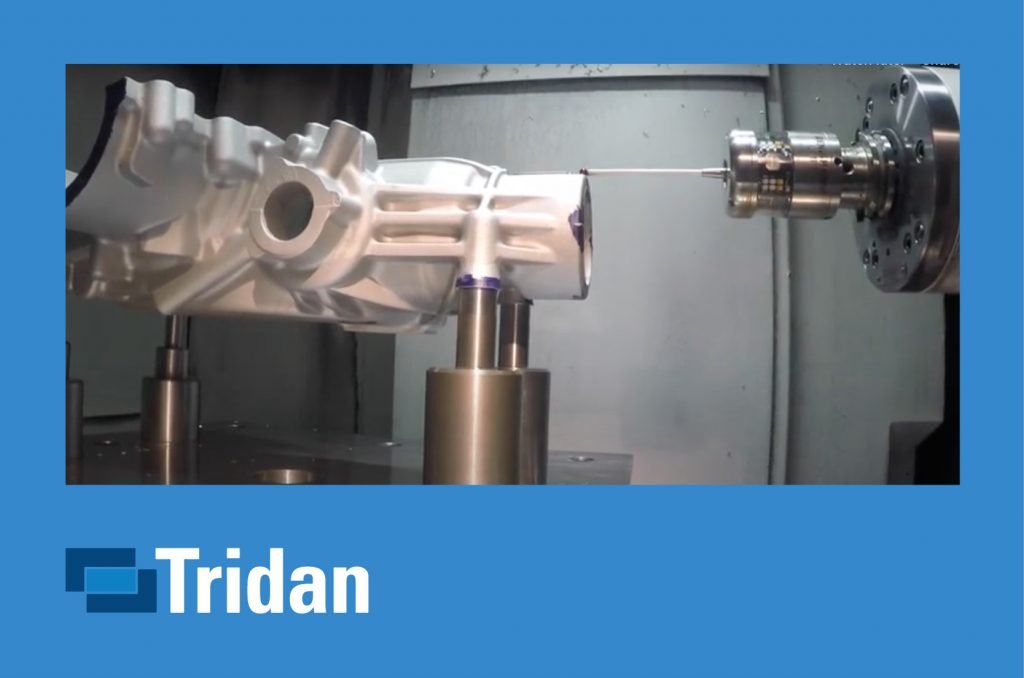

Tridan now manufactures 30 off various components. These components are manufactured and held as stock at Tridan and called off when required by Kanban.

The Kanban quantity is for two weeks production. Tridan manufactures in batch sizes of three times Kanban, this allows our customer flexibility to increase production at short notice, as all parts are picked from Tridan stock.

Tridan engineers continue to work closely with our customers design engineers in an effort to improve the current products and enhance future ventures. In 2013 savings of 15% on machining costs were realised thro’ design for manufacture and continuous improvement on existing parts.