Problem

A leading US-based manufacturer of biomedical instruments opened a manufacturing facility in the UK to make instrument modules for final assembly at the company’s American HQ.

Problems with delivery, quality and price stability soon arose as the instrument components were supplied from many sources including UK-based and US-based suppliers as well as in-house manufacture.

Solution

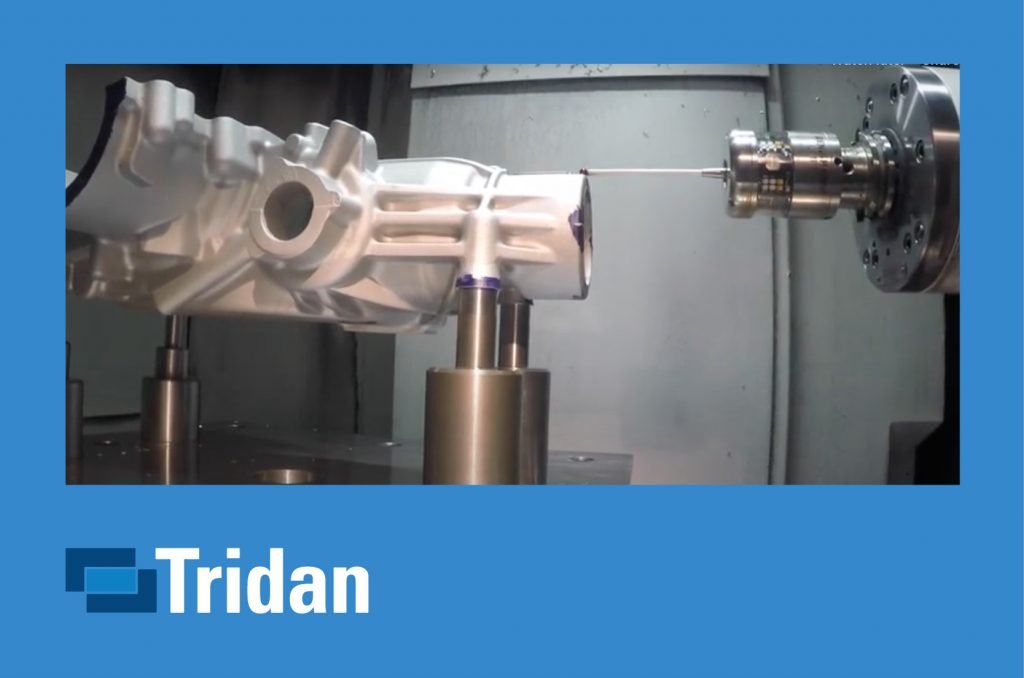

Having found Tridan Engineering and its partnership development successes via our website, contact was made leading to a supply agreement for machined parts and assemblies.

Tridan currently supply 75 various components for this company – a total of approximately 5000 parts per month. These are supplied on a just in time (JIT) basis against a rolling schedule that can be varied to suit the customers build requirements.

Outcome

The company now uses Tridan as the principal supplier to its cutting edge manufacturing facility in the USA.

As well as slashing overheads, the customer now enjoys a relationship with a proactive supplier involved in product development through helping to design components for manufacture, in turn reducing part costs.