The challenge

In our tenth month we are looking at our KPI’s and customer/supplier weekly schedules.

Taking the lead on our first continual improvement case study in February is Mike Newman, our Operations Director. Mike discusses how we set, maintain and evaluate our KPI’s along with showing you the system we use to record these.

Our next February case study will be led by Emma Smith, Senior Production Controller, discussing customer/supplier weekly schedules.

Everything we do is precision focused so our task was to find those small areas of improvement and showcase how they make an overall big improvement.

Next month we’re looking at Tridan in the community and our tooling partnerships.

CASE STUDY 1 – KPI’S

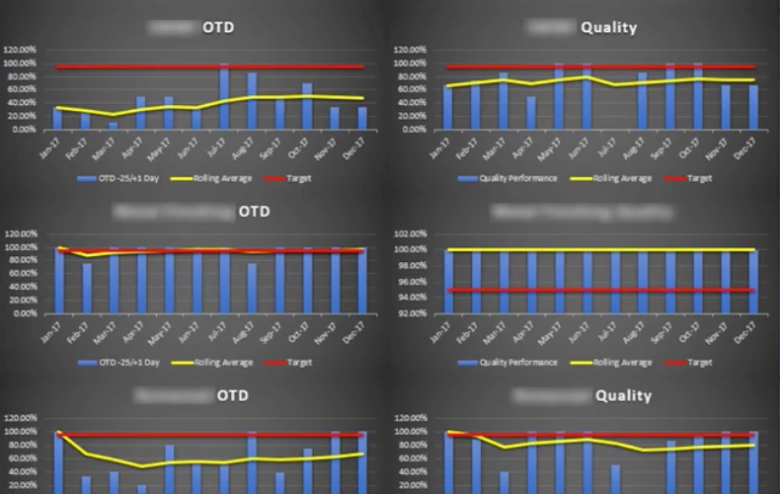

KPI’s are a very important part of our continual improvement activities. We use the data to identify where and how our efforts will be best used.

Over the years we have refined the information we analyse and have created a bespoke KPI dashboard where all the information is viewed in one place. All of our process owners are responsible for their own KPI’s and the actions taken from them but we also sit as a multi-functional team to discuss and identify trends. From this meeting actions are agreed with time lines and owners appointed.

We flow our KPI performance down through the business in various formats to suit the audience and ensure that the data is shown is “bite sized” to hold people’s attention.

The KPI performance is also flown up and down our supply chain to ensure as we improve so do our customers and suppliers.

”Over the years we have refined the information we analyse and have created a bespoke KPI dashboard where all the information is viewed in one place.”

CASE STUDY 2 – CUSTOMER/SUPPLIER WEEKLY SCHEDULES

At Tridan we are always looking for continual improvement, with this in mind, when I became the Senior Production Controller for Tridan Engineering I saw an opportunity to improve the way we communicated with both our customer and suppliers.

We started sending over weekly order books to our key customers. This is essentially a spreadsheet that shows all outstanding orders for that customer and gives us the chance to update them with forecast dates and any comments/updates relating to orders. We find this opens the channels of communication, helps to build rapport and form a more collaborative relationship with our customers.

In line with our collaborative approach, we adapt our open order books to suit the needs / requirements of our customers. We have a standard layout for our order books as our MRP/ERP system allows us to export all the relevant information which we can then manipulate into a customer order book. A few of our customers have a template layout that we have adapted and used, and another key customer has an order book within their online portal system which we keep updated daily. We are flexible in our approach as the idea of the order books is to make the lives of our customers as easy as we possibly can!

We have implemented a similar process for our suppliers; we send over a forward load once a week with a forecast of all work that will be arriving within the next six-month period. This has proved helpful in many areas, firstly we are reserving capacity with the supplier as they know exactly when our work will be arriving. Secondly, we list out all processes and customer specifications and send copies of the drawings well in advance, this gives the supplier a chance to query or question anything with us before parts arrive and stops anything being held up.

The feedback we have had from both our customers and suppliers proves that the new approaches we are taking are working very well. We have been told that the information provided is clear, concise and most importantly time saving! I personally also believe that it has greatly improved our working relationships.