The challenge

In our fourth month we ‘re looking at our HR and Conventional operations.

Managing Director, Paul Hawkins introduces this month’s first continual improvement by discussing Tridan’s people strategy and communications.

For the second case study of the month Paul Coupland, Machine Shop Manager, discusses Tridan’s ability to manufacture all jigs/fixtures on site and how this benefits our customers.

Everything we do is precision focused so our task was to find those small areas of improvement and showcase how they make an overall big improvement.

Next month we’ll be looking at our new BMS AS9100 and Health and safety continual improvements.

HR-

Our People strategy

Crucial to our success has been getting the right structure and people in place to work within our organisational values of respect, reliability, teamwork, passion, integrity and autonomy. Changing some of our old-fashioned management styles from authoritarian and ‘do what you are told’ to encouraging our team to have a voice and use their own initiative has been undertaken through a process of learning and development, and creating a culture of autonomy.

We have introduced a coaching culture from the top down and operate on a management belief that individuals can find the answer. We work on the principle of asking a question rather than providing the answer. This coaching approach allows everyone to lead by instilling accountability and responsibility down through the organisation – encouraging the team to find solutions, not present problems.

Communication and engagement are also key features in our plan. Everything from the company vision and objectives, quality of work and ideas for business improvement to feedback, training and development are regularly discussed with the team. We are passionate about training and continuous improvement, with our latest core of managers having recently undertaken leadership training through an outsourced training.

The word “appraisal” has been banned from Tridan and we now operate an Annual Summary Review (ASR), this is a document that all team members will sit with their line manager and discuss.

The usual criteria includes:

- The quality of work

- Communication

- Time keeping

- The individuals understanding of the mission/vision statement and values

- Do they feel part of the mission/vision statement and values?

- Do they have any concerns in how Tridan are moving forward?

The ASR then goes onto focusing on the performance of their line manager and what can be done to improve from them, or indeed the company. Are there any suggestions throughout the company we can improve? This could be lean initiatives, communication or whatever the individual would like to discuss. The last part of the ASR comes back to the individual on how they would like to develop in the coming year. This is the opportunity to make sure we understand the needs of all team members including what training they would like, if they would they like to move into another department etc. This new method has proved very successful, and more importantly we do not miss an individual’s desire to improve.

Another positive change we have made is through the quarterly newsletter which every member of the team receives.

The newsletter is themed and this year’s theme is football. The football themed topic includes:

- Match analysis – this is where we give a brief overview of customer/supplier meetings, and any major audits that have taken place.

- Team performance – discuss all KPI’s, plus mention last quarters outstanding performance from team members, then three are selected as winners – where they receive a £50 prezzo voucher each as a thank you.

- League position to date – all financials are discussed, from budget to actual figures.

Other topics include:

- Tridan in the community (money raised for local charities, school/college presentations etc.

- Team news at Tridan (special birthdays, marriages, retirement etc).

- Upcoming fixtures (customer/supplier meetings to be held in the next quarter).

- We shoot, we score (new contracts awarded, etc.)

- New players/training (new team members who have joined, who have completed training etc).

The last topic is managers comment, this is where the MD wraps up the newsletter, and will do a quick overview of how the company is performing.

The newsletter is informative, with some humour thrown in, it is a very light-hearted way to get out very important information. More importantly, everyone throughout the company knows what is going on. This of course is a massive help in us all driving Tridan forward to achieve our goals.

JIG/TOOLING/ CUTTER GRINDING –

If you can’t hold it, you can’t machine it

Your only as good as your last part, or to be precise, the way you machined your last part. Whatever way you look at it, work holding is just as important as the final machining.

As the title says, “If you can’t hold it, you can’t machine it”.

We pride ourselves on being the ‘essential engineering component’. We can offer our customers a complete manufacturing package, from design input all the way through to finished parts, in both castings and raw material, from plastics to exotic metals.

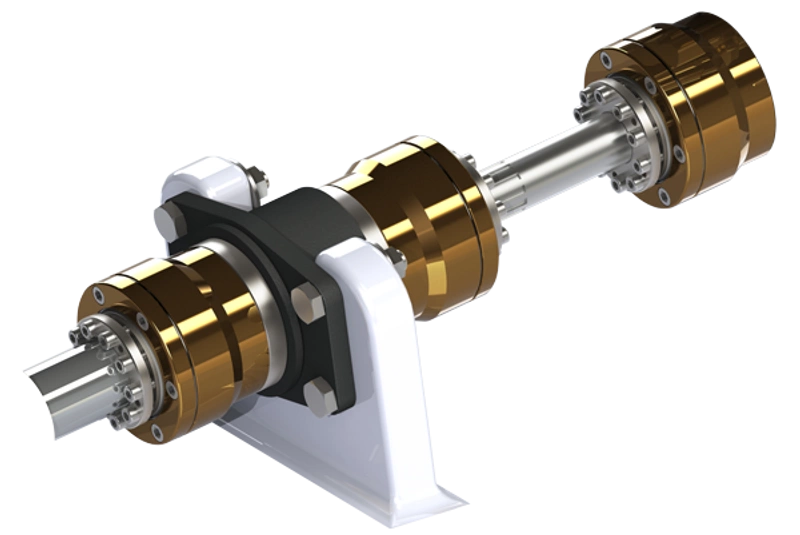

Due to the diversity of parts we machine across different sectors, from food and medical to high end motorsport and aerospace/defence, one service we offer as part of the package, is the ability to machine our own specialist jigs and fixtures in house.

The jig and fixture cell is specifically dedicated to manufacturing our in-house work holding. This benefits both Tridan and its customers by maintaining control over the whole manufacturing process, and cost/time reductions, as there is no need to outsource.

We have the capability to manufacture jigs and fixtures for components 1.5 metres in length, down to small high precision parts for both milling and turning.

All fixtures are securely stored and documented for future orders, saving remake costs and reducing customer lead times, after all our parts are only as good as the jig/fixture they are machined on, poor work holding = poor parts.