New machine investments & continual improvement review

The challenge In our seveneth month we ‘re looking at

In our twelfth month we discuss our plans for the future and give an overview of the continual improvement campaign over the past 12 months.

Our Machine Shop Manager, Paul Coupland takes lead on the penultimate case study of the campaign and shares with you our plans for the future and how we will continue to improve as a company.

For the final case study of the campaign Managing Director, Paul Hawkins, shares his favourite months from the continual improvement campaign and how far Tridan have come as a company but also where we are heading.

Everything we do is precision focused so our task was to find those small areas of improvement and showcase how they make an overall big improvement.

I would like to thank you for joining us in sharing our passion for continuous improvement over the past 12 months. I thought that we should finish by not looking back but looking forward at the implementations we are going to introduce over the coming months.

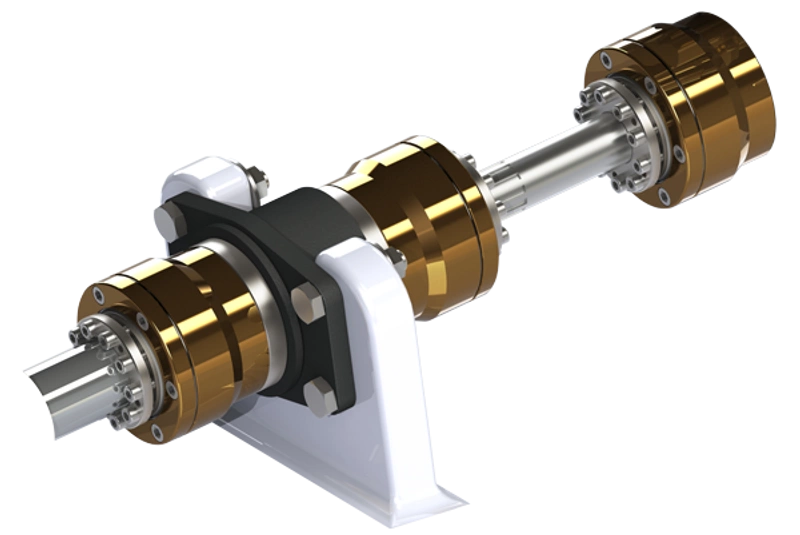

Our new 5-axis cell is almost up and running, the machine is in and producing parts, the multi pallet system is due on site at the beginning of June. Once fully operational we will gain an extra 300+hrs per month. This combined with a new weekend shift we are currently recruiting for will give us the potential for unattended lights out running 24/7.

We are introducing a new shift pattern to expand our already productive shop floor; this shift will run Fri – Sun and will enable our unattended machines to be monitored and kept fed with material to minimise any potential down time.

Our recent machine acquisitions are proving their worth, and the next round of machine tool investment is currently under review, so watch this space…

We have been extremely lucky in the market place with our latest recruitment drive and we hope this will continue with the recruitment currently under way.

We are moving, well my office and department is moving to make way for an updated and expanded assembly area, this will be located directly beside our Final Inspection area and will enable parts to be moved from assembly to Inspection, then onto dispatch in a fully air-conditioned and clean environment. A clean room is also being installed to handle the more complex assemblies that our aerospace customers require.

As we are celebrating our golden anniversary, I personally am looking forward to the celebration we have planned alongside a competition we are running with a local secondary school STEM groups. There are multiple groups of all ages taking part and the winner of the eldest age group will win the chance of an apprenticeship with us.

Talking of apprenticeships, Tridan will be looking to again take on and train the next generation of engineers, we are looking to take on 3-4 in various roles across the company.

As I said earlier, thank you for joining us and I look forward to showcasing our future improvements over the coming months.

The challenge In our seveneth month we ‘re looking at

The challenge In our Eleventh month we are looking at our tooling

The challenge In our tenth month we are looking at our

The challenge In our eighth month we ‘re looking at our